ECE R136

important in brief

ECE R136

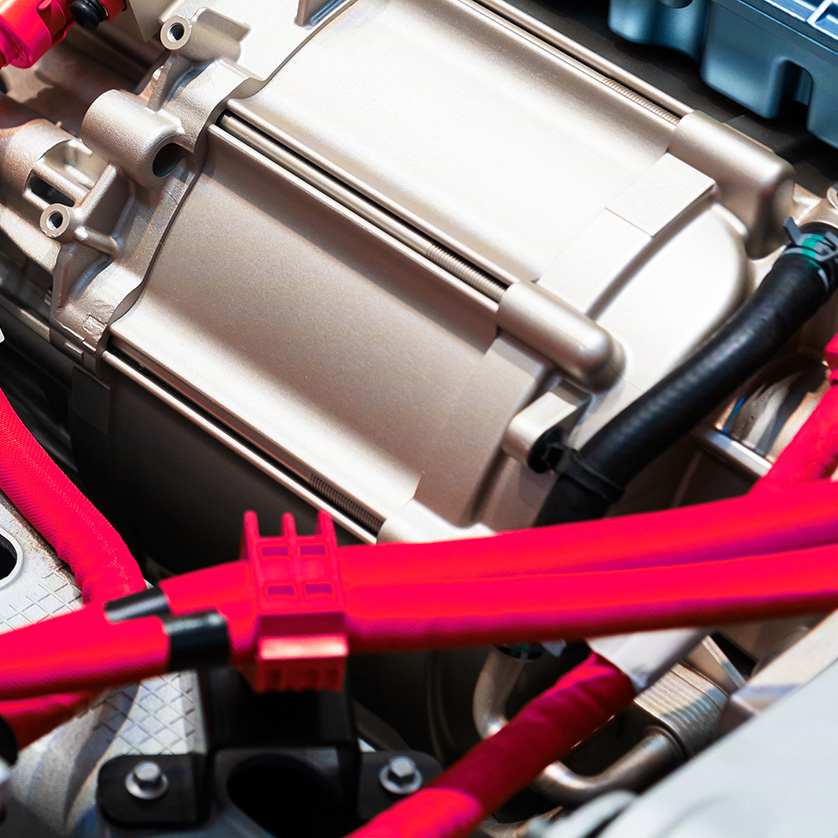

ECE R136 is an internationally recognized UN regulation that defines specific safety requirements for the electric drive and the rechargeable energy storage system (REESS) of class L vehicles. It serves as a binding framework for the type approval of light electric vehicles such as e-scooters, motorcycles, mopeds and four-wheeled light vehicles and is therefore a central component for safe market access in the field of micromobility.

Batteryuniversity is an independent testing laboratory specializing in the safety-related testing and certification of electric drive and battery systems. We offer you all relevant tests for obtaining an ECE R136 type approval, including vibration, thermal shock, drop and short-circuit tests for REESS as well as insulation and dielectric strength tests for high-voltage systems. Our test procedures comply with the latest regulations of the United Nations Economic Commission for Europe (UNECE) and take particular account of the special conditions to which class L vehicles are exposed in urban use.

Why we are the right partner for ECE R136

Certified test laboratory

As an independent and accredited test laboratory, we reliably guide you through all test phases of ECE R136 certification. Our test reports meet the formal requirements for type approval in accordance with UN/ECE regulations. This is the basis for international market access for your electrified vehicles.

Many years of experience

With over 15 years of experience in testing batteries and electric drives, we have in-depth technical knowledge that is specifically geared towards standards such as ECE R136. Our experts will guide you safely through the entire certification process, from test planning to successful completion.

All tests from one source

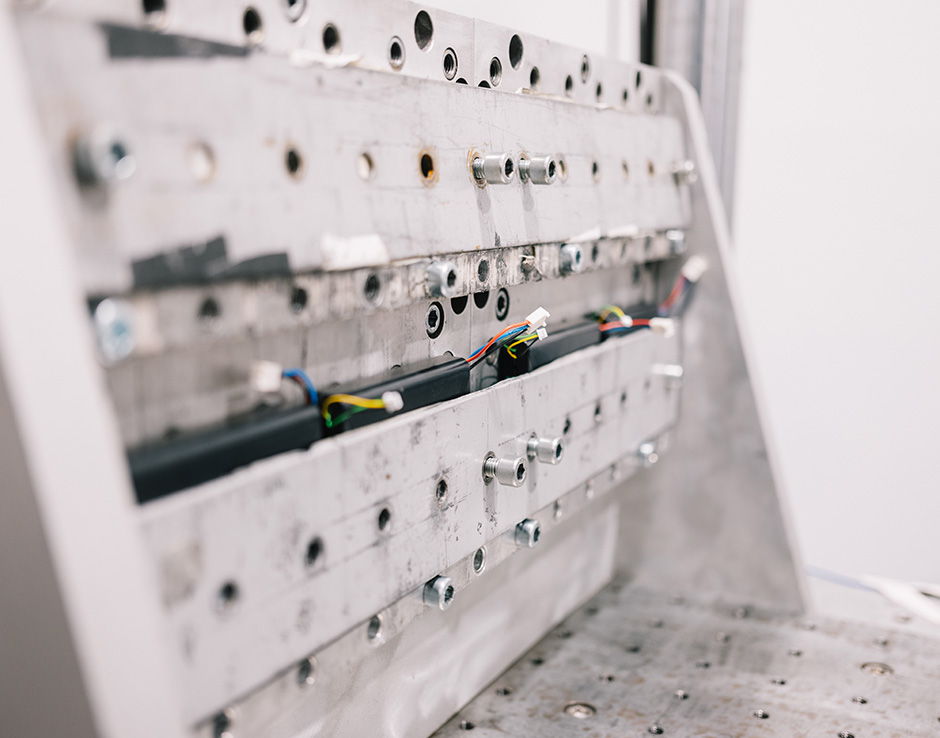

Whether high-voltage systems or rechargeable electrical energy storage systems (REESS), we carry out all ECE R136 tests directly in our laboratory. This includes tests for vibration, thermal shock, overtemperature, fire resistance, mechanical impact and short-circuit protection.

Efficient and rapid implementation

Thanks to clearly defined procedures, efficient processes and application-oriented advice, we can guide you quickly through the ECE R136 certification process. This saves you time and money and allows you to bring your product to market on time.

Latest testing technology

Our laboratory has state-of-the-art measurement technology and specialized testing equipment designed for safety-relevant tests in accordance with ECE R136. We test both complex REESS systems and high-voltage components and use advanced technologies to ensure standard-compliant and reproducible results.

Customized testing concepts

Class L electric vehicles such as mopeds, motorcycles or four-wheeled light motor vehicles differ significantly in their design and technology. Our test procedures are precisely tailored to the respective requirements in order to enable standard-compliant and reliable certification in accordance with ECE R136.

The role of ECE R136 in the electromobility of tomorrow

With the global shift towards electromobility, the importance of standardised safety requirements for electric drive systems is increasing. ECE R136 was developed by the United Nations Economic Commission for Europe (UNECE) to define binding safety requirements for the electric drive and the REESS of class L vehicles. These include electric motorbikes, electric scooters and four-wheeled light vehicles. The regulation ensures that high-voltage systems and rechargeable energy storage systems (REESS) function reliably and safely under realistic conditions. Stresses such as temperature peaks, vibrations and mechanical effects are taken into account.

A high safety standard is essential, especially in urban areas where these types of vehicles are frequently used on a daily basis. ECE R136 helps to recognise and avoid hazards such as thermal runaway, short circuits, overcharging or insulation faults at an early stage. At the same time, it provides a clearly structured framework for type approval, which is an essential prerequisite for access to European and international markets. As a technical standard, it not only fulfils safety-related regulations, but also serves as a strategic tool for manufacturers who want to successfully position their products worldwide.

How we guide you through the ECE R136 certification process

ECE R136 certification involves a series of demanding tests that affect both the electrical safety system, such as insulation and dielectric strength, and the battery system (REESS). Our experienced team will accompany you every step of the way. Together with a technical service, we first carry out a detailed inspection of the vehicle class, the electrical structure and the energy storage system used. Based on this, we plan all the necessary tests together. This includes, among other things:

Abuse tests

-

Short circuit

-

Overloaded

-

Overtemperature

Mechanical tests

-

Vibration

-

Shock

Environmental tests

-

Thermal shock

-

Fire resistance

Once the tests have been completed, you will receive a comprehensive test report from us, which serves as proof to the approval authorities. In addition, we offer you support with the application for approval and inform you about deadlines, transitional regulations and future standard updates. Our aim is to make your certification not only legally compliant, but also as smooth as possible. This enables you to bring your product to market quickly and successfully.

FREQUENTLY ASKED QUESTIONS & ANSWERS

ECE R136 is a UN regulation that defines standardised conditions for the type approval of L-category vehicles with regard to their electric powertrain and energy storage system. It is crucial for access to international markets and the legal authorisation of these vehicles within the framework of the UNECE regulations.

ECE R136 applies to vehicles in category L, i.e. electrically powered two-, three- and light quadricycles (e.g. e-scooters, electric motorbikes, light vehicles) with a maximum design speed of over 6 km/h that are not permanently connected to the power grid. ECE R100, on the other hand, is aimed at vehicles in categories M and N, i.e. classic passenger cars and commercial vehicles, and specifies safety requirements for the REESS, electrical components and hydrogen emissions. It is therefore relevant for four-wheeled road vehicles with higher performance and other application profiles.

The regulation specifies requirements for high-voltage systems and rechargeable electrical energy storage systems (REESS), including insulation, dielectric strength, short-circuit protection, overcharge and overtemperature protection as well as mechanical resilience (e.g. in the event of vibration or fire). The aim is to reliably minimise electrical and thermal risks.

ECE R136 concerns REESS systems (Rechargeable Energy Storage Systems) that are used in class L vehicles and are used to supply the electric drive. Batteries whose main purpose is to start the engine or supply lighting and auxiliary consumers are excluded.

Compliance with ECE R136 enables type approval on the basis of internationally recognised UN regulations and thus facilitates market access in many countries. Manufacturers also benefit from greater confidence in the safety and reliability of their products, which strengthens their competitiveness in the EV market.

As an independent test laboratory with specialised equipment, we offer all tests in accordance with ECE R136 from a single source - including vibration, thermal shock, short-circuit and fire resistance tests. Our many years of experience and modern laboratory technology enable efficient, precise testing processes and reliable support on the way to type approval.

INFORMATION ABOUT THE AUTHOR

Alexander Roth

Alexander Roth is head of the test laboratory at Batteryuniversity and an expert in the testing and certification of lithium-ion batteries.