ECE R100

IMPORTANT IN BRIEF

ECE R100

The ECE R100 is a binding UN regulation that defines safety-related requirements for high-voltage components with electric drives in vehicles. It plays a central role in the approval of battery electric and hybrid vehicles within Europe and ensures that high-voltage batteries and their electrical protection systems function reliably under a wide range of conditions. Manufacturers, suppliers and vehicle developers are obliged to fulfil the extensive requirements of ECE R100 before their systems can be placed on the market.

As an independent and accredited test laboratory, we support you with all tests in accordance with ECE R100, whether type testing, temperature change testing, vibration or protection against electric shock. Our services include tests in accordance with Annex 9, e.g. electrical safety as well as mechanical and thermal safety of the UNECE regulation. We attach particular importance to fast project processing, transparent communication and complete test reports.

What makes us the ideal partner for the ECE R100

Recognised test laboratory

As an independent and accredited test laboratory, we are very familiar with the complex requirements of ECE R100. We deliver test results that comply with international UNECE standards - a prerequisite for the approval of your high-voltage battery systems in European motor vehicle traffic.

Industry experience

With over 15 years of experience in testing battery systems for the automotive industry, we know exactly what is important for ECE R100 approval. Our experts are familiar with both the current regulatory developments of the UNECE and the requirements in OEM projects.

Tests from a single source

Whether electrical safety, mechanical load or thermal stability, we provide you with all tests in accordance with Annex 9 of ECE R100 in one place. Our test capacities cover almost the entire spectrum, including tests for vibration, short circuits, overcharging, temperature changes and more.

Fast project realisation

Our well-rehearsed processes enable all tests to be carried out quickly. In this way, we support manufacturers from numerous nations in the rapid approval of their electric vehicles.

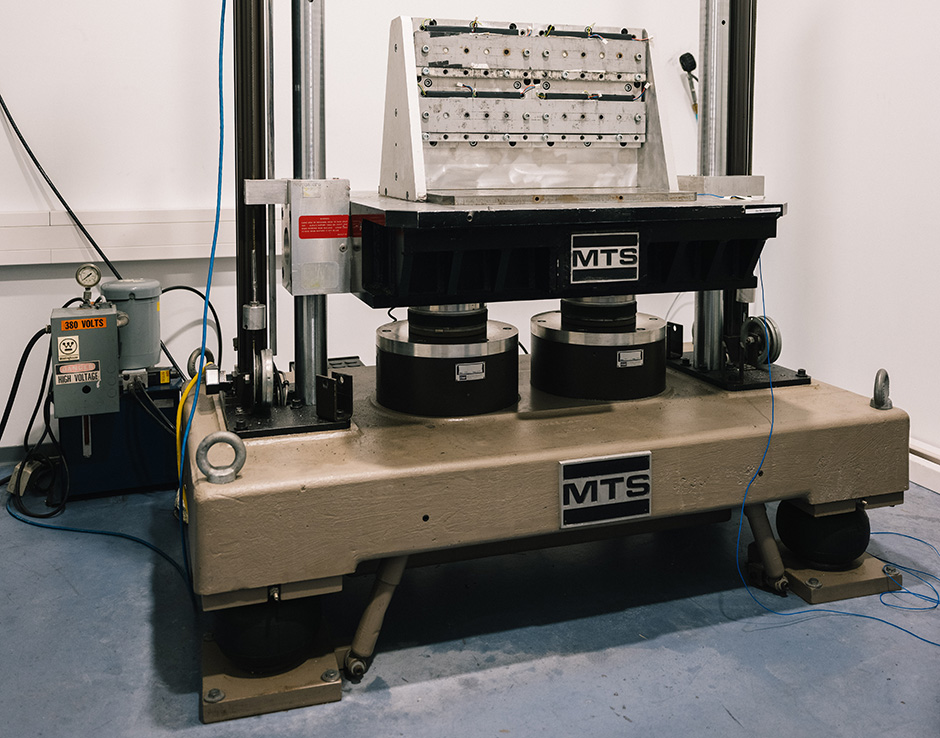

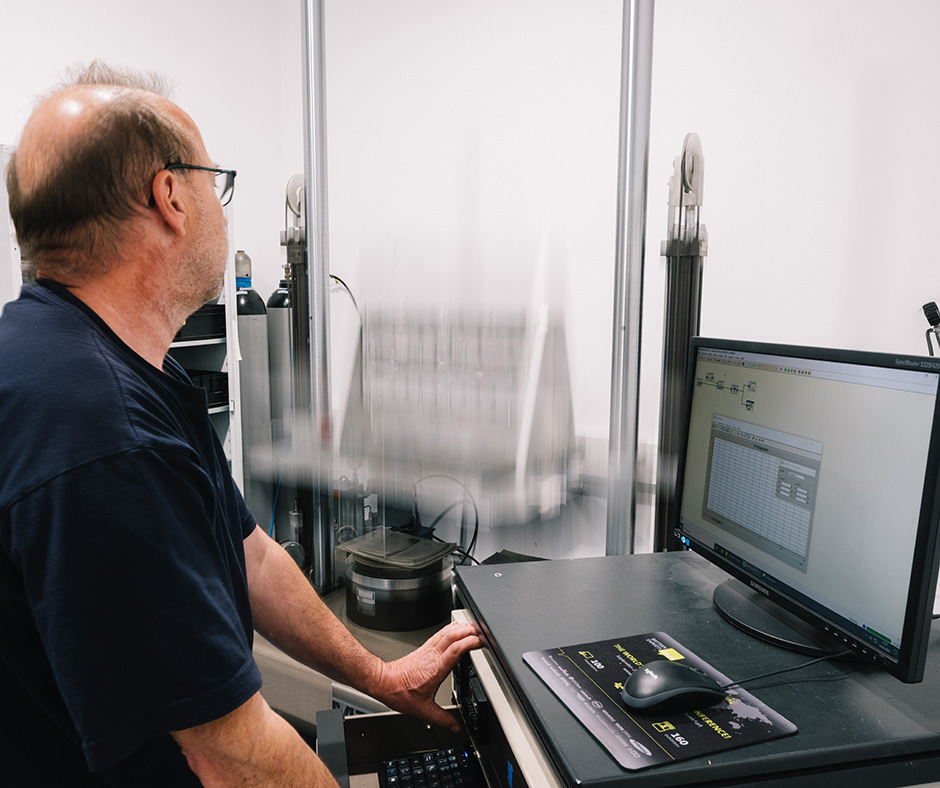

Latest laboratory technology

Our laboratory is equipped with state-of-the-art testing technology for high-voltage batteries, including tests for battery modules of all common types. We not only test passenger car applications, but also motorbikes, commercial vehicles and other vehicle types.

Customised testing strategies

Every battery system presents its own challenges. We develop specific testing strategies for complete systems, individual components and battery modules so that you can reliably fulfil all the requirements of the UNECE regulations.

Why the ECE R100 is indispensable for battery systems in vehicle development

The ECE R100 is more than just a formal approval requirement, it is an essential part of the safety concept for modern vehicles with electric drives. For manufacturers of high-voltage battery systems in particular, the standard ensures that the components used can withstand mechanical, thermal and electrical loads and do not pose a hazard under real-life conditions.

The constantly increasing performance requirements for battery packs in electric vehicles, for example in terms of range, fast charging or crash safety, are also increasing the regulatory hurdles. The ECE R100 provides a standardised test framework that is recognised globally in the context of UNECE type approval. For development departments, this means that the requirements of the standard must be taken into account early on in the development process in order to avoid expensive rework and project delays. A standard-compliant system in accordance with ECE R100 is therefore not only technical proof of safety, but also creates confidence among authorities, OEMs and end customers alike. Those who plan and have their systems tested in accordance with standards at an early stage secure decisive advantages in the approval process and on the European market.

Download UNECE Agreement

Our testing and certification process for your ECE R100 conformity

The path to ECE R100 certification begins with a thorough analysis of your battery system: We evaluate cell chemistry, battery modules, housing design, electrical protection measures and mechanical properties and derive the standard-relevant tests from this. We focus on the test modules of ECE R100: Annex 9 A to J. We carry out tests in our laboratory in accordance with Annex 9 of the UNECE regulation, including:

Abuse tests

-

Short circuit

-

Overloaded

-

Forced discharge

-

Over-temperature

Mechanical tests

-

Vibration

-

Shock

-

Mechanical integrity

Environmental tests

-

Thermal shock

-

Fire resistance

Our experts are on hand to advise you throughout the entire process, from the selection of suitable test strategies to standard-compliant documentation. Once all tests have been successfully completed, you will receive a detailed test report that serves as the basis for ECE R100 approval. Our goal: smooth, fast and transparent certification with maximum planning security for your product development.

FREQUENTLY ASKED QUESTIONS & ANSWERS

The ECE R100 is a mandatory basis for the type approval of electric and hybrid vehicles in Europe. It ensures that the high-voltage system fulfils the safety requirements with regard to electrical, mechanical and thermal influences.

ECE R100 applies to four-wheeled electric and hybrid vehicles. ECE R136, on the other hand, is aimed at motorbikes, three-wheeled vehicles and light four-wheeled vehicles such as e-scooters or quads.

The test requirements of ECE R100 are defined in Annex 9 of the UNECE regulation. They include insulation, protection against electric shock, overcharging, thermal shock, short circuit, vibration and fire resistance.

The ECE R100 refers to high-voltage battery systems, in particular those with a nominal voltage above 60 V. It does not generally apply to 12V low-voltage batteries.

Successful ECE R100 certification is a prerequisite for vehicle authorisation in Europe. It also signals a high level of product safety to authorities, OEMs and end customers, which significantly increases market acceptance.

As an experienced and independent test laboratory, we offer all relevant tests in accordance with ECE R100 from a single source. With state-of-the-art laboratory technology, standard-compliant test methodology and comprehensive advice, we guide you efficiently through the entire certification process.

INFORMATION ABOUT THE AUTHOR

Alexander Roth

Alexander Roth is head of the test laboratory at Batteryuniversity and an expert in the testing and certification of lithium-ion batteries.